PANASONIC AUTOMATES HAELVOET PRODUCTION LINE WITH G4 WELDING ROBOT SYSTEM

Panasonic's TAWERS G4 welding robot system provides the desired production flexibility and accuracy for Haelvoet, a leading provider of medical furniture. Munich, DE. July 24, 2025 - Panasonic Factory Solutions and its long-time partner SYN-TIG have upgraded the production line of medical furniture manufacturer Haelvoet with Panasonic's TAWERS G4 welding robot system. This enables manufacturing supplier Grovinvest to significantly increase flexibility and automation in the production of specialty medical devices for customers across Europe. The modernized production line at Grovinvest's factory in northern Romania enables the seamless production of four variants of Haelvoet's medical bed frames. Already in 2009...

PANASONIC AUTOMATES HAELVOET PRODUCTION LINE WITH G4 WELDING ROBOT SYSTEM

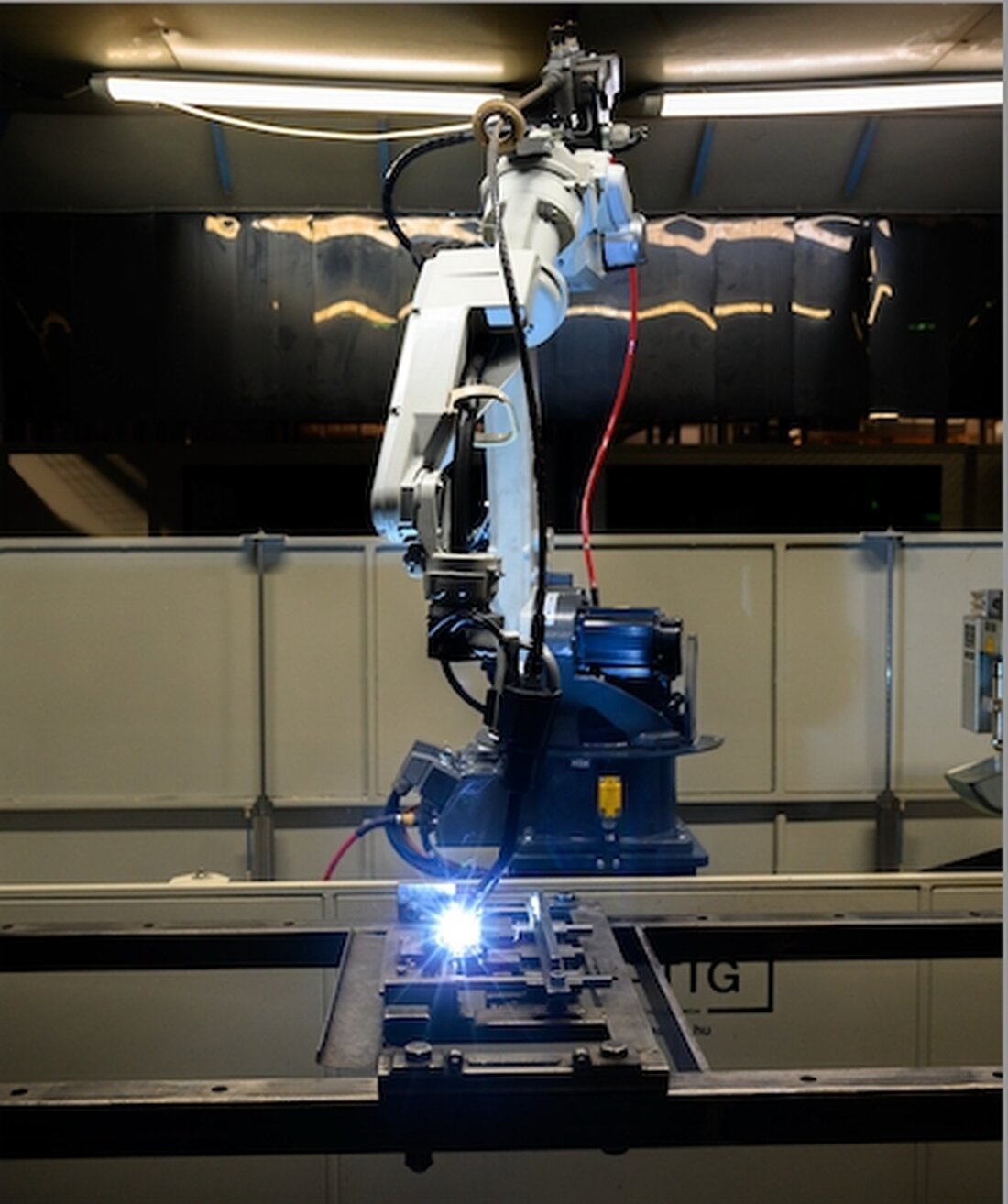

Panasonic's TAWERS G4 welding robot system provides the desired production flexibility and accuracy for Haelvoet, a leading provider of medical furniture.

Munich, DE. July 24, 2025 - Panasonic Factory Solutions and its long-time partner SYN-TIG have upgraded the production line of medical furniture manufacturer Haelvoet with Panasonic's TAWERS G4 welding robot system. This enables manufacturing supplier Grovinvest to significantly increase flexibility and automation in the production of specialty medical devices for customers across Europe.

The modernized production line at Grovinvest's factory in northern Romania enables the seamless production of four variants of Haelvoet's medical bed frames. The factory first used earlier versions of Panasonic's robot cells in 2009, which were upgraded in 2014. TAWERS G4 automatically detects all required components before starting production. It also delivers the required welding precision and speed while minimizing start-up time.

Automation as the key to faster production

The advanced integrated welding robot system optimizes welding process management in a single controller for high-speed, high-quality arc welding. It is characterized by increased processing speeds of the controller and optimized communication between the controller and the robot. Compared to previous models, the smaller TAWERS G4 not only saves space, but also costs - without compromising reliability.

Additionally, the G4's teach pendant touchscreen simplifies programming on the production line. Consumables, such as contact tips, last longer than previous models. This means there is no need to keep excessive spare parts and maintenance downtime is minimized.

The G4 also features offline programming software that enables real-time digital remote access to production and plant operating data. This allows Grovinvest engineers to reprogram either all or only specific parts of the welding process while the robot is still running.

Bogdan Pienaru, Managing Engineer of Haelvoet contractor Grovinvest, says: "Regardless of the size of the components used, Panasonic's G4 immediately starts the required manufacturing program, saving valuable time when switching between manufacturing programs. The welding quality of the G4 is excellent; Panasonic continues to set standards in welding precision, speed and accuracy. Overall, our modernized production line and the service from Panasonic and SYN-TIG are an ideal fit."

You can find the full case study here

About Panasonic Group

Founded in 1918, Panasonic Group is now a global leader in the development of innovative technologies and solutions for a wide range of applications in the consumer electronics, housing, devices, B2B solutions and energy sectors and has transitioned to an operating enterprise system on April 1, 2022, with Panasonic Holdings Corporation serving as the holding company. The group reported consolidated net sales of 51.6 billion euros (8,458.2 billion yen) for the fiscal year ended March 31, 2025. Further information about the Panasonic Group can be found here: https://holdings.panasonic/global/

About Panasonic Connect Europe GmbH

Panasonic Connect Europe began operations on October 1, 2021, creating a new business-to-business oriented and agile organization. With more than 400 employees and led by CEO Shusuke Aoki, the company aims to contribute to its customers' success with innovative products and integrated systems and services - all designed to realize its vision to transform work, advance society and connect with the future.

Panasonic Connect Europe is headquartered in Wiesbaden and consists of the following business areas:

-Mobile Solutions: The fail-safe, modular TOUGHBOOK notebooks and tablets, combined with 5G technology, private 5G networks and an extensive portfolio of services, increase the productivity of mobile employees in their daily work on the go. Custom hardware services kits are available as a monthly Mobile IT as a Service subscription.

-Media Entertainment includes, on the one hand, the Visual System Solutions with a wide range of powerful and reliable projectors as well as high-quality professional displays. And on the other hand, Broadcast & ProAV for Smart Live Production solutions from an end-to-end portfolio of PTZ and system cameras, camcorders, the Kairos IT/IP platform, switchers and robotics solutions, which are widely used for live recordings at events, sports productions, on television and in xR studios.

-Business and Industry Solutions: Innovative supply chain solutions for retail, logistics and manufacturing with the unique Gemba Process Innovation approach, developed together with all process participants to increase operational efficiency, better realize end customer wishes and automate or digitalize processes. The projects are handed over on a turnkey basis – integrated into the existing IT infrastructure.

-Panasonic Factory Solutions Europe sells a wide range of smart factory solutions, including electronics manufacturing solutions, robotics and welding systems, and software for the entire manufacturing process.

Further information can be found at: https://eu.connect.panasonic.com/de/de

Please visit the Panasonic Connect Europe LinkedIn page: https://www.linkedin.com/company/panasonic-connect-europe/

Company contact

Panasonic Marketing Europe GmbH

Stefan Hauck

Hagenauer Strasse 43

65203 Wiesbaden

+49 894 535 410 22

http://connect.panasonic.eu

Press contact

FInk&Fuchs AG

Patrick Rothwell

Berliner Strasse 164

65205 Wiesbaden

0611 7413116

https://www.ffpr.de

The image rights belong to the author of the message.

Suche

Suche

Mein Konto

Mein Konto